15 Factors That Impact the Cost of PCB Assembly

Understanding the key elements that drive the cost of PCB assembly is essential for manufacturers aiming to optimize their production budgets. Each decision, from PCB design to component sourcing, directly impacts the overall expenses. In this article, we delve into 15 crucial factors that determine PCB assembly costs and explore solutions to streamline these processes.

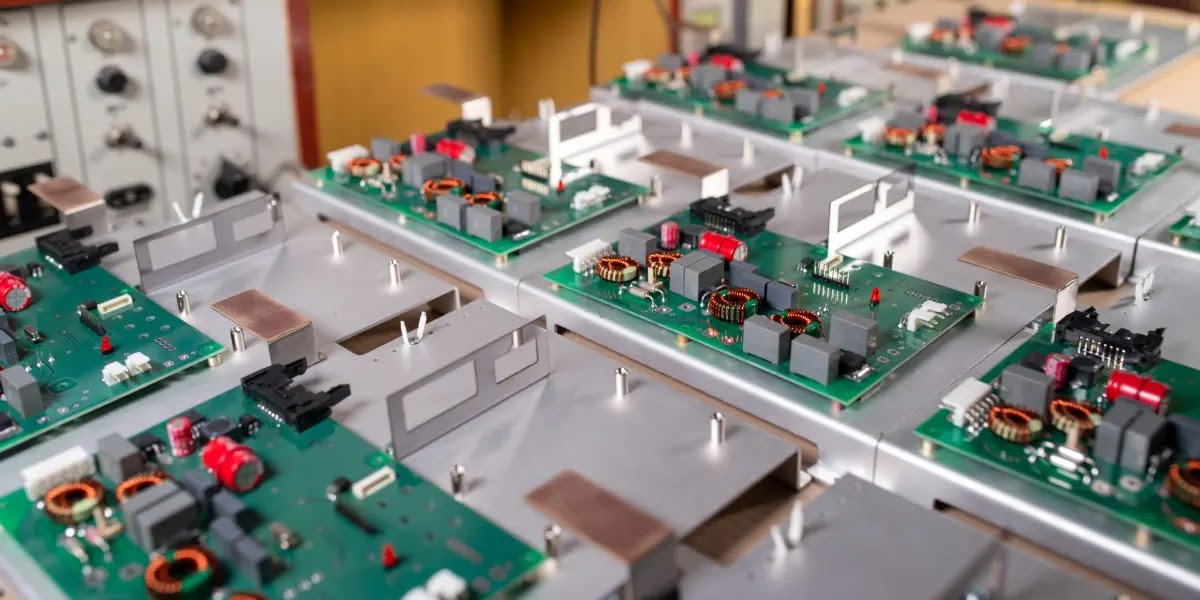

1. Complexity of PCB Design

The intricacy of a PCB design heavily influences the cost. Multi-layer boards with complex layouts require advanced techniques and longer production times, making them pricier to assemble.

2. PCB Size and Shape

Unconventional shapes or larger boards demand more material and specialized handling, which can drive up assembly expenses. Smaller, simpler designs are generally more affordable.

3. Material Type

The type of material used in your PCB assembly—whether it’s FR4, aluminum, or high-frequency substrates—affects the cost. Premium materials ensure better performance but come at a higher price.

4. Components Used

Advanced or rare components increase costs. From resistors to microcontrollers, the price of components plays a critical role in the total cost of PCB assembly.

5. Assembly Type: SMT or Through-Hole

Surface Mount Technology (SMT) is often more cost-effective due to its automated process. In contrast, through-hole assembly involves manual work, making it a more expensive option for some designs.

6. Component Sourcing

If the PCB assembly service provider sources components, they may charge a fee for procurement. Availability, shipping, and bulk ordering discounts also influence the final cost.

7. Labor Involvement

While automation minimizes human involvement, specific tasks may require skilled labor, such as assembly for highly customized or intricate boards, adding to overall expenses.

8. Quantity

Producing a higher volume of PCBs can reduce per-unit costs. Bulk orders spread out setup and production expenses, making larger runs more cost-efficient.

9. Lead Time

Urgent orders with shorter lead times tend to be more expensive. Expedited production requires prioritization, which increases labor and processing costs.

10. Testing and Quality Control

Extensive testing, such as AOI or functional testing, ensures the reliability of your product but also adds to the assembly cost. Comprehensive quality checks are an investment in long-term product success.

11. Customization Requirements

Personalized options, such as non-standard solder masks, unique finishes, or branding elements, can elevate costs due to the added work and materials needed.

12. Regulatory Standards

Meeting industry certifications like RoHS or ISO compliance involves adhering to strict protocols, which adds value but also increases costs for PCB assembly services.

13. Packaging and Shipping

Safe packaging and reliable shipping solutions protect assembled PCBs during transit. The cost depends on the type of packaging material and shipping method used.

14. Manufacturing Overheads

Factors like electricity, equipment maintenance, and operational costs indirectly influence assembly pricing. Efficient manufacturers minimize overhead impacts, keeping costs competitive.

15. Service Provider Expertise

Selecting an experienced PCB assembly service provider makes a difference. A reliable partner minimizes delays, reduces errors, and provides cost-effective solutions tailored to your project.

How Anzer Adds Value to Your PCB Assembly

Anzer stands out as a trusted partner when it comes to optimizing PCB assembly costs. Our team helps businesses streamline their processes, from PCB design to final assembly. We leverage advanced manufacturing techniques, reliable sourcing networks, and efficient operations to deliver high-quality results at competitive prices.

Whether you need assistance with sourcing components, meeting tight deadlines, or scaling production, Anzer provides tailored solutions to meet your specific needs. Our commitment to transparency and customer satisfaction helps deliver your projects on time and within budget.

Conclusion

The cost of PCB assembly depends on several factors, from the complexity of the PCB design to material choices and lead times. By understanding these elements, you can better plan your projects and control expenses. Partnering with a trusted PCB assembly service provider like Anzer Provides high-quality boards and cost-effective solutions.

Contact Anzer today to discuss your project and discover how we can help you achieve efficient and affordable PCB assembly.

Comments

Post a Comment